I have the PLX SM-AFR unit with the DM-100 gauge. I only have one forward stock narrowband O2 sensor, so I replaced my stock sensor with the wideband sensor. The SM-AFR unit will simulate a stock narrowband signal to the PCM. The SM-AFR also includes output so you can wire it into the HPT EIO interface.After you install the WB, you will scan using the WB input which will give you a much more accurate AFR.

From there, you can fine tune. In my case I adjust MAF and PE values based on the AFR I see in various ranges.

If you have access to a dyno you can figure out the best AFR for your setup and always try to tune around that. Without the wideband you are just guessing at optimal AFR.The DM-100 gauge is sweet. It has various display modes and can be customized to display any background pic you want. The really nice advantage of the DM-100 is that you can program warnings. For instance, I can set it to warn me if my boost is over xx psi and AFR is more than 12.5, or something like that.

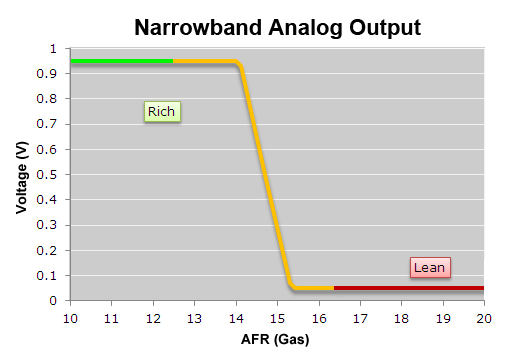

It will actually flash a big warning message, and I can back off the throttle before I blow something up. Check out the PLX website for a demo video. Let me get this straight, I can just swap a stock narrowband for the wideband and the car will still operate normally as if it was still the stock narrowband sensor. How do you hook it up to your car so it will do the fueling adjustments, does it have a harness to hook right up to the car, as well as being able to run a gauge and hook up to HPTuners???You can't just swap any wideband. There must be a signal converter. Narrowband signal is 0-1v and wideband is 0-5v.

PLX gives you this signal converter in their setup. Read this:It is not completely plug-n-play.

To install the PLX WB, you remove your narrowband sensor from the exhaust, and install the WB in the same bung. There are usually four wires that run from the PCM to the narrowband: 1) Signal, 2) Ground, 3) Heater power, 4) Heater Ground. Since the WB heater does not get its signal from the PCM, you have to fool the PCM into thinking the sensor heater is working ok. This is done by installing a 20ohm resistor between the heater power and heater ground. Then you run the stock signal and ground wires from the PCM into the PLX converter. The converter also has output connections so you can run wires from the converter to an HPT Pro interface. (If you don't have the HPT Pro, there are other ways to get the wideband signal into HPT, but you have to know a lot more about your specific PCM wiring.)The PLX is fairly easy to install, except you have to run wires everywhere and figure out where to mount the resistor(s).

Since I have my EGR removed, I used that bolt hole on the block to mount my resistors on a small piece of metal. I used two 10ohm resistors instead of one 20ohm.Fueling adjustments are done by the PCM, not the O2 sensor.

The sensor just returns a value indicating to the PCM how rich or lean the fuel mixture is in the exhaust. The PLX converter will take the WB AFR reading and convert it back to narrowband for the PCM. For example, if your exhaust AFR is 11.8, the PLX will convert that to something like 930mv and send that to the PCM for fueling calculations. I would choose a WB that has the ability to do free air calibration like the Innovate LC-1 or NGK AFX.That issue comes up a lot about PLX.From the PLX website:'Other products on the market which require calibration use an unconventional control technology not recomended by Bosch. This is designed to reduce manufacturing costs and places the burdon of having the user calibrate the sensor.PLX devices widebands are all meticulously calibrated from the factory, and gives you 'plug and play' usability.'

'The LC-1 and the LM-1 both use an unconventional method of controlling the o2 sensor which is not the recomended control method according to the Bosch Datasheets. The PLX wideband control circuirty was designed according to the specific requirments directly from the Bosch datasheets which does not need any manual calibration.These Bosch sensors are utilized in OEM Porsch, VW, and several other european manufacturers directly.

The driver never has to manually calibrate the wideband sensor throughout the entire duration of the ownership of the vehicle.In short, proper design of a wideband controller requires the Bosch sensor to be plugged in and used, without ever having to manually recalibrate the wideband controller.' Well i ordered the plx setup with the D5 gauge.i know there is a harness to hook the WB up to the sensor box, but is there a wire harness to hook up the analog feature to the stock narrowband o2 sensor wire (so i can replace the narrowband and not have to cut wires up) and hptuners box???

I had an extension harness for my stock O2 wiring from when I first installed my headers. I just cut this and fabricated a couple connectors on the end of the cut wires.There is a recommended distance from the engine for the wideband sensor, but I can't remember the exact distance. You will get the info in the instructions, or check out the forums on PLX.I've seen a lot of people talk about calibrating the LC-1, and how it is required, but I haven't yet heard of anyone saying their PLX was not calibrated correctly. I know they have a series of tests you can run against the sensor to test for accuracy, one of which is to run it in open air, but I think that just checks that it is functioning properly. I've been using mine for a few months now in a daily driver, and trims have locked in perfectly. I run right on the edge of knock in WOT and have been able to dial in some good fueling and timing. I ran my PB at the track before the wideband, and I think now that I have a solid tune, I'm going to drop that at least a half second.

Here is what I plan to do.need some helpI will be replacing the stock NB sensor with the WB on a 2002 Camaro Z28.I plan on disabling the SES light for the stock heater and capping those wires off under the car. I am gonna hook the 1Volt analog output to the stock sensor harness under the car so it will still operate as if a stock sensor is there, then hook the 5Volt analog output to the PCM EGR pin so i can log through that sensor using HPTuners.My question is, Do I need to hook up the capacitor anywhere in my setup since I am not using a 3rd party scanner directly hooked to the 5volt analog line, like I said the analog lines will both be connected back to the car o2 sensor harness/pcm pin. I will be logging the WB through the EGR sensor from OBDII portAlso will it matter where I pull my 12 volt ignition power and place my ground at with this setup, I seen on here it says to get power/ground as close to the pcm as possible, but dont understand why???Any help or feedback is greatly appreciatedAlso I plan on using the IGN auxillary hookup on the fuse box on the left side of the dash, do i need to add an inline fuse holder or is it already fused? From PLX instructions:'Install the noise filtering capacitor across Chassis GND and O2 Signal Input as close as possible to the ECU. This eliminates unwanted electrical noise and increases close loop ECU performance.'

If you don't install the capacitor on the O2 signal, you will throw a code for insufficient signal count. The PCM expects the O2 sensor to swing from rich to lean a number of times in a set period to verify it is working correctly.

I tried not installing the capacitor, and I got the DTC.Since you are using the EGR to send the signal to your scanner, I don't think you need to use the capacitor, but I'm not positive. Might want to ask over on the PLX forums.I'm not positive why you have to get power so close to the PCM. Something to do with seeing the same reference ground. I just got an email from plx and in it they said 'install 2 10ohm 20W resistor in between heater + and - to fool ECU, or OBDII cars 1k ohm 10W'in this post it said to use 20 ohm not 1k ohm??????I don't know about the 1K ohm resistor. I used exactly what they said in the instructions:'.You may use two 10 Ohm 10 Watt resistors connected in series as an alternate solution. Radio Shack part#271-132.'

Plx Wideband O2 Install Itunes Code

I got the exact part at Radio Shack and installed them as described. I've never had a DTC for the O2 heater, so I'm guessing it works fine. Can I just turn off the DTC code for the passenger side O2 sensor heater (since that is the one i am replacing with WB), instead of using a resistor??? Or will that through the pcm into a different mode or something???if not how hot does the resistor get, just trying to figure how to secure it and with what to secure it with?I thought about just disabling the DTC as well.

Plx Wideband O2 Install Itunes Account

I looked through the service manual and couldn't find anything that said the failed heater code would cause any problems. But then I was in Radio Shack and saw the resistors, and they were only a couple bucks, so I picked them up.The resistors are ceramic blocks with wires out each end.

I fabricated a small metal square with a hole in the center, and then epoxied the resistors onto each side of the metal square. I soldered one end of the resistor leads to each other and the other ends ran to the heater wires. I mounted the metal square onto the engine block in the spot where the EGR used to be (mine is removed because of intercooler). Since this spot in the engine is right next to the header pipe crossover, I figured heat would not be a problem.